Manufacturing

Manufacturing Facilities That Improve Operations

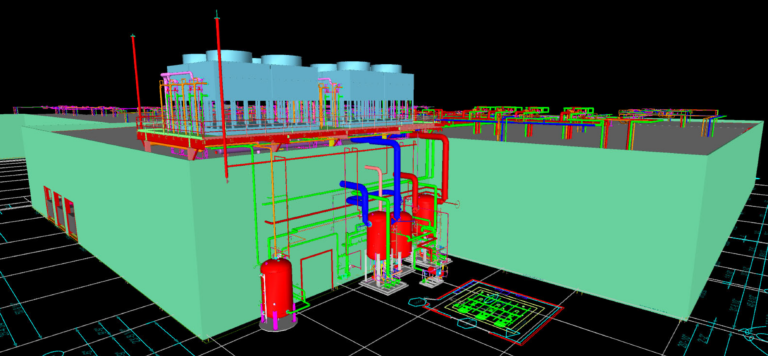

Manufacturing facilities are measured by their efficiency, durability, safety, and overall value. Across the nation, Corval Group delivers expert insights and total solution capabilities that optimize your run rate, temperature control, tank storage, pipework, and any other aspect that’s critical to production.

Solving Your Process Challenges

All manufacturing facilities place high demands on durability while also seeking operation efficiency and quality. Extreme conditions, caustic materials, acidic gases, and harsh parameters are the norm. That’s why Corval Group facility projects are built to last and overachieve in their functionality. A manufacturing plant construction project is no place for amateurs. We provide experienced engineering solutions, precision equipment placement, and unsurpassed build quality. A facility’s longevity, efficiency, and ongoing safety depends on it.

Respected Throughout the Industry

Manufacturing facilities are tools with a job to do. How well they perform a task depends on the company behind the designs, engineering, fabrication, and construction. Corval Group is a nationally respected partner bringing experience and total solution capabilities to your project.

- Chemical Processing

- Metal Processing

- Manufacturing

- Waste Diversion

Let’s Find Your Facility Answer

As Vice President leading Corval’s Commercial and Industrial Construction groups, Chris delivers results with a focus on client care. Chris is an alum of the Minnesota State University-Moorhead’s Construction Management program and active in the AGC. He developed his problem-solving approach to managing projects and teams over the course of 21 years in the Construction industry. Chris stewards resources to allow his Corval teams to meet the schedule, budget, safety, and quality requirements required on the project through focused efforts in meeting the client’s overall project expectations.

Manufacturing Facilities That Deliver

When manufacturing clients need new or renovated facilities, there’s no better EPC partner than Corval Group. We do it all from preconstruction planning to pouring concrete, placing equipment, final handover, and ongoing maintenance.

Here is a sampling of our best work within the manufacturing industry.

PURIS Proteins, LLC – Production Facility

Louis Dreyfus – Crush Facility

CertainTeed – Asphalt Unloading Station

HaF/Jabil – Cryogenic Milling

Gerdau

Freedom Fuels, LLC – Biodiesel Facility

Dow Corning – Midland Chemical Conversion

Glacial Lakes Energy – Facility Expansion

Corval has experts in my industry. They know what we need to get ahead.

Client Name, Title

Safety Comes First

Our safety culture, programs, training, and systems help us live up to the motto, “No One Gets Hurt.”

Corval Group is a Single-Source Solution

Corval Group offers dimensional capabilities that can be contracted as stand-alone offerings or bundled and provided through one of our various delivery methods to meet a facility project’s specific requirements.

Project Development

Innovative approaches from site selection to state/local economic development participation to turnkey financing solutions for facility projects.

Preconstruction

Gathering perspectives from key stakeholders and using careful analysis to create a detailed plan for construction success.

Engineering

Expert engineering for complex refrigeration, process facilities, and complex mechanical systems.

Construction

Meeting the need with turn-key EPC or design/build services as well as construction management or general construction capabilities.

Refrigeration

Robust engineering, design, and construction capabilities for any refrigeration system, method, or cooling application.

Fabrication

Expert craftspeople with more than 60,000 square feet of fabrication space and tooling to meet industrial and commercial needs.

Special Projects

Handling small projects and difficult challenges including tight deadlines, budget constraints, habitation issues, and other scenarios that can jeopardize a project.

Service and Maintenance

Keep a facility operating to specification with 24/7 emergency and as-needed service.